Silica Dust – A Safe Work Month Focus

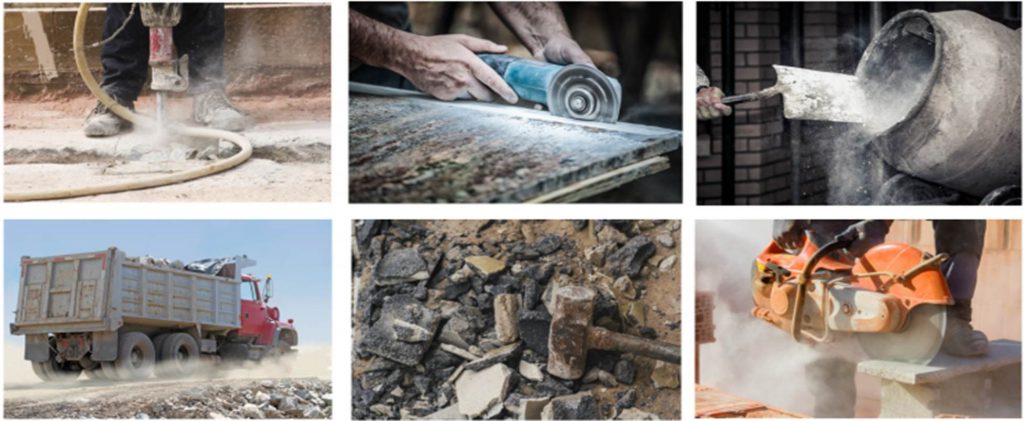

Silica dust (crystalline silica) is found in some stone, rock, sand, gravel and clay. The most common form is quartz. Silica dust can also be found in the following products:

- bricks

- tiles

- concrete

- some plastic material.

When these materials are worked on, silica is released as a fine dust known as respirable silica dust.

Silica dust is harmful when inhaled into your lungs. As it is 100 times smaller than a grain of sand, you can be breathing it in without knowing. Exposure to silica dust can lead to the development of lung cancer, silicosis (an irreversible scarring and stiffening of the lungs), kidney disease and chronic obstructive pulmonary disease. It is estimated that 230 people develop lung cancer each year as a result of past exposure to silica dust at work. The occupations with the greatest exposure include:

- miners

- construction workers

- farmers

- engineers

Breathing in more than the amount of silica dust shown in this picture, per day, means you have exceeded the exposure limit of 0.1mg/m3 .

All Australian workplaces must follow work health and safety laws; however, these vary slightly between states and territories, but the duty of care for employers and responsibilities of workers across Australia is similar.

An organisation that uses any of the materials noted above and who have staff performing these types of tasks have a responsibility to control silica exposure and have a management plan in place. Within reason, workers must take care of their own health and safety, not negatively affect that of others and follow instruction and workplace health and safety policies.

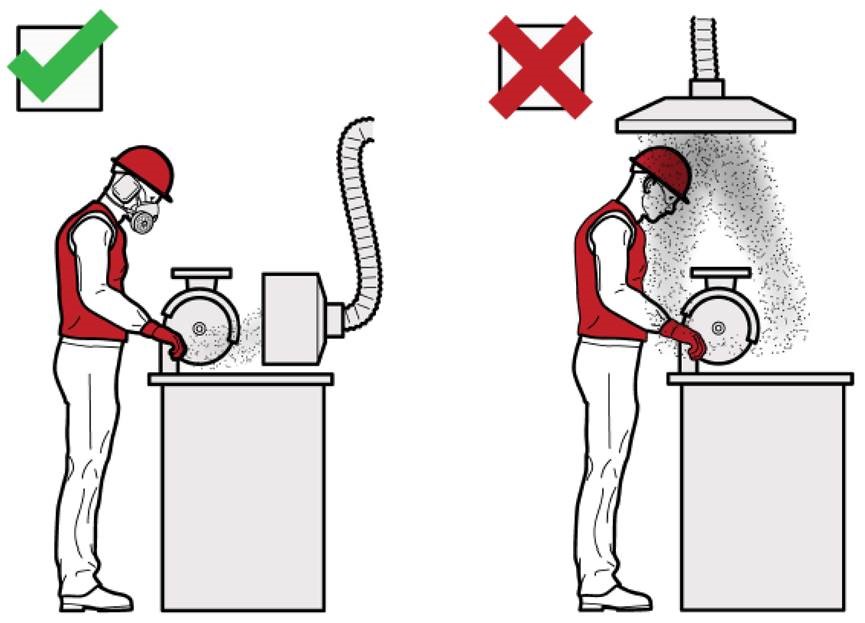

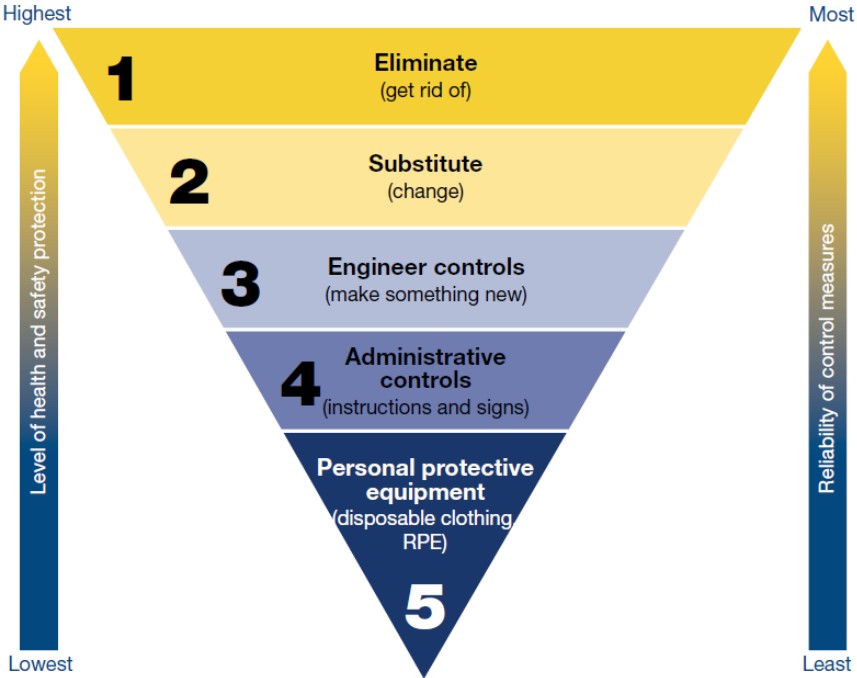

The hierarchy of control is a useful tool to guide employers in implementing control measures. Elimination is the most effective and reliable protection measure. Attempts to isolate the job so that there is no exposure to silica or increasing the ventilation to reduce the amount of silica in the air should be made.

In some cases, elimination may not be possible if silica dust is naturally occurring at your workplace or you can’t make the end product or deliver a service without generating it.

- adopting production processes that generate less dust, for example, any wet method is likely to generate less dust than a dry one

- treating the dust at the point of generation, as this is more effective than capturing airborne dust, and

treating the dust on its transmission path using dust suppression techniques, for example, water sprays, chemical additives, local exhaust ventilation (LEV), vacuum